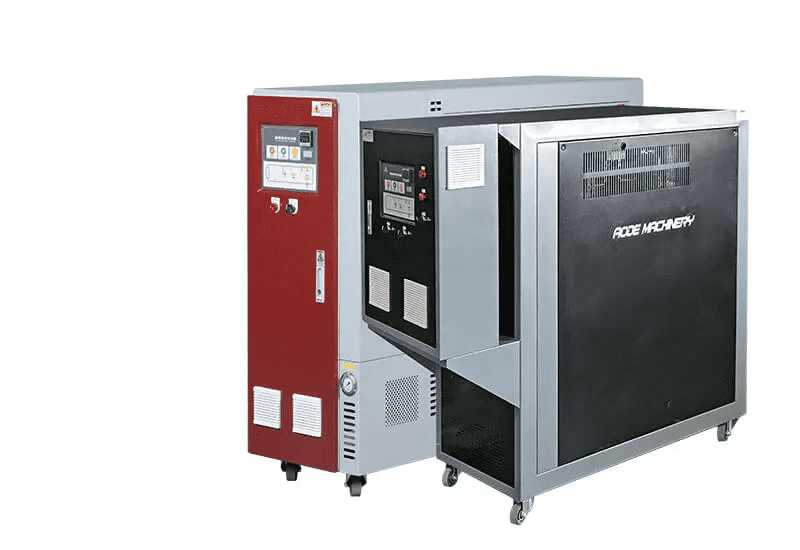

Oil temperature control units made from AODE are high quality, as a leading oil temperature control unit manufacturer and supplier from China, we operate over 14,000 square meters of industrial park space for factory production. This is our main page of oil temperature control unit, following we will comprehensively and deeply discuss what is an oil temperature control unit, common applications, the value it brings to enterprises, and maintenance technical support, etc.

Preview Navigation:

|

1. Introduction to Oil Temperature Control unit1.1 What is an Oil Temperature Control Unit?1.2 History of oil temperature control unit1.3 Why is an oil temperature control unit important in industrial processes? |

2. How Oil Temperature Control Units Work2.1 Basic Working Principle2.2 Key Components

2.3 Comparison: Oil vs Water Temperature Control Units | 3. Applications of Oil Temperature Control Units3.1 Industries Using Oil TCU

3.2 Use Case Examples |

4. Technical Specifications and Features4.1 Temperature Range4.2 Heating Power and Oil Flow Rate4.3 Control Accuracy and Interface4.4 Safety Protection Systems | 5. Types and Models5.1 Standard vs High-Temperature Units5.2 Portable vs Fixed Units5.3 Customization Options |

6. Leading Manufacturers and Brands6.1 Top Global Suppliers6.2 Recommended Chinese Manufacturers6.3 OEM/ODM Capabilities | 7. Buying Guide and Price Range7.1 Factors to Consider Before Buying7.2 Estimated Price Range7.3 Where to Buy and Factory Direct Options |

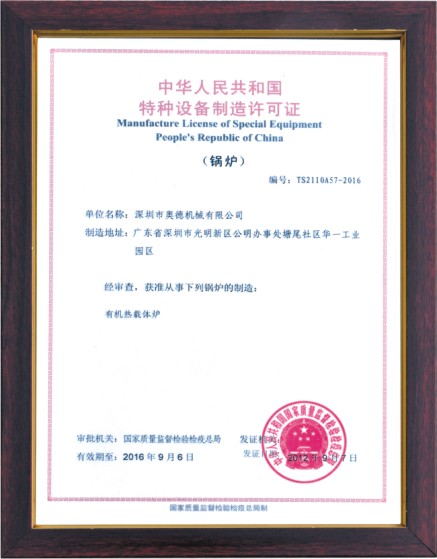

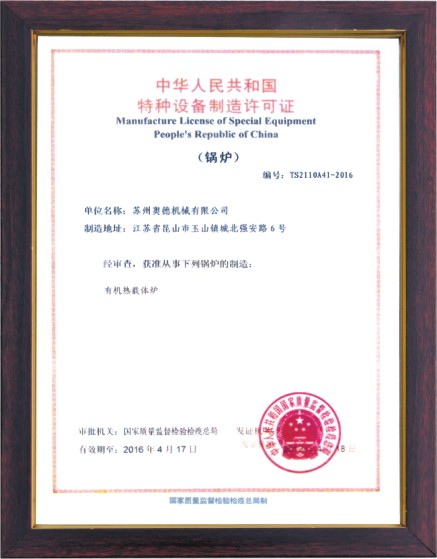

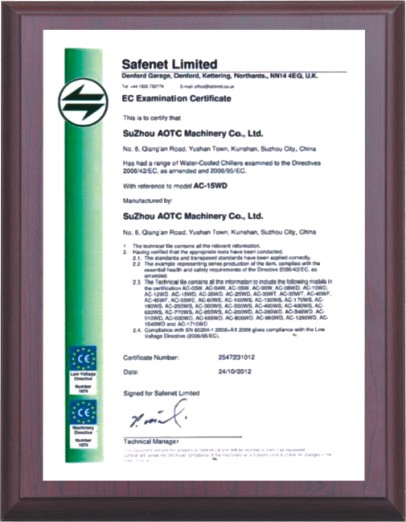

8. Installation, Operation & Maintenance8.1 Installation Tips8.2 Operating Instructions8.3 Routine Maintenance & Oil Replacement8.4 Troubleshooting Common Issues | 9. Safety Standards and Certifications9.1 CE, UL, ISO Compliance9.2 Built-in Safety Features |

10. Energy Efficiency & Environmental Impact10.1 Smart Temperature Control10.2 Eco-Friendly Heat Transfer Oil10.3 Energy Consumption Comparison | 11. Customer Reviews and Case Studies11.1 Real-World Applications11.2 User Feedback and Ratings12. Frequently Asked Questions (FAQs) |

Introduction to Oil Temperature Control unit

What is an Oil Temperature Control Unit?

An Oil Temperature Control Unit (Oil TCU) is an industrial device used to precisely control the temperature of thermal oil circulated within machinery or molds. It is widely applied in industries such as injection molding, die casting, rubber processing, and pharmaceuticals, where stable and high-temperature control is critical. The unit heats oil using electric heaters and circulates it through a closed loop, maintaining consistent temperature via a PID controller. Standard oil temperature control unit typically operates within a range of 45°C to 180°C, while high-temperature oil temperature control unit can range from 25°C to 400°C, making them ideal for processes requiring high thermal stability. By ensuring uniform heat distribution, oil TCUs enhance product quality, reduce cycle times, and extend equipment life, significantly improving operational efficiency and consistency in industrial manufacturing.

History of oil temperature control unit

The history of oil temperature control unit as following:

Origin: Oil temperature control unit emerged in the mid-20th century to meet the precision heating needs of plastics and rubber molding industries.

Development: In the 1980s–1990s, PID control and safety features improved, expanding use to die casting and pharmaceutical sectors.

Advancements: With digitalization in the 2000s, touchscreen interfaces, PLC integration, and remote monitoring became standard.

Today: Modern oil temperature control unit offers eco-friendly designs, high-temperature stability (up to 400°C), and are essential in smart manufacturing and Industry 4.0 environments.

Why is an Oil Temperature Control Unit Important in Industrial Processes?

An oil temperature control unit (TCU) is crucial in industrial processes because it ensures precise and stable temperature regulation for thermal oil circulation. This stability prevents overheating, reduces thermal stress, and maintains optimal production conditions. By delivering uniform heat, oil temperature control unit improves product consistency, reduce defects, shorten cycle times, and extend equipment life. They also enhance energy efficiency and minimize downtime, offering significant cost and performance benefits across sectors like plastic molding, die casting, and chemical manufacturing.

Key Benefits:

|

|

|

How Oil Temperature Control Units WorkBasic Working PrincipleAn Oil Temperature Control Unit (TCU) operates by heating thermal oil with electric heaters and circulating it in a closed-loop system through machinery or molds. A built-in pump moves the oil, while a PID controller monitors and adjusts the temperature precisely. The system ensures uniform and stable heat transfer, essential for maintaining consistent processing conditions, improving product quality, and protecting equipment from thermal damage. |

Components of an Oil Temperature Control Unit

Detailed inforamtions of Components of an Oil Temperature Control Unit by AODE as following

| Heater | Electric heaters with adjustable heating capacities (from 12kW to 240kW) are used to raise the thermal oil temperature rapidly and efficiently. |

| Oil Pump | High-power oil pumps (1.5kW–15kW) with flow rates ranging from 6.5 to 50 m³/h ensure continuous and stable oil circulation through the system. |

| Control Panel | Equipped with a PID temperature controller (±1°C accuracy), enabling precise monitoring, temperature adjustments, and process optimization. |

| Safety Devices | Multiple safety functions: inverse phase protection, oil shortage alarm, overheating protection, overload trip, oil overflow alarm, and abnormal heating detection. |

| Heat Transfer Medium | Specially formulated thermal oil, designed for stable heat conduction and high-temperature operation (up to 300°C). |

| Cooling System | Indirect cooling method using water pipes (1/2 inch standard), helping to cool the oil when necessary. |

| Expansion Tank | Provides space for thermal oil expansion (24L to 300L), protecting the system from pressure build-up. |

| Power Supply | Standard 3-phase 380V 50Hz industrial power supply, ensuring consistent operation across models. |

| Piping & Connections | Circulating water pipe sizes range from 1 to 2 inches, designed for efficient integration into industrial systems. |

| Frame & Structure | Durable housing with compact dimensions, suitable for various industrial installations. |

Oil vs. Water Temperature Control Unit – Professional Comparison

Temperature control units (TCUs) include oil temperature control unit and water temperature control unit, both are critical in precision temperature management for industrial processes such as injection molding, die casting, chemical reactions, and more. But water Temperature Control Unit (WTCU) and Oil Temperature Control Unit (OTCU) differ significantly in performance, application range, and operation method.

Water temperature control unit typically uses either direct or indirect cooling and is limited by the boiling point of water. The water temperature control unit is ideal for applications requiring temperature control up to 180°C and offers faster heat transfer and lower operational costs. In contrast, Oil temperature control unit operates at much higher temperatures, up to 400°C, thanks to the high boiling point and stability of thermal oil. They are widely used in high-temperature applications that require consistent heat and safety.

Each type has its own advantages and limitations based on medium, temperature range, accuracy, safety features, and cost. Below is a comprehensive table comparing the features of both systems.

Comparison Table: Water vs. Oil Temperature Control Unit

| Feature | Water TCU (WTCU) | Oil TCU (OTCU) |

|---|---|---|

| Heat Transfer Medium | Water | Thermo Conductive Oil |

| Cooling Method | Direct or Indirect | Indirect |

| Temperature Control Range | Up to 150–180°C | Up to 300°C |

| Temperature Accuracy | PID ±1°C | PID ±1°C |

| Heating Capacity (kW) | 6 – 24 (Basic models) / up to 240 (Advanced models) | 6 – 24 (Basic models) / up to 240 (Advanced models) |

| Cooling Water Pipe Size | 1/2 inch | 1/2 inch (or none for some models) |

| Circulating Water Pipe Size | 3/8" to 3/4", varies by model | 3/8" to 2", varies by model |

| Pump Flow Rate | 40 – 235 L/min or 7–12.5 m³/h | 30 – 240 L/min or 6.5–50 m³/h |

| Pump Pressure | Up to 12 kg/cm² | Up to 50 m |

| Max Power Consumption (kW) | 9.75 – 27.75 (basic) / up to 255 (advanced) | 7 – 27.75 (basic) / up to 255 (advanced) |

| Expansion Tank | Not required (in most models) | Required (24 – 300L depending on model) |

| Alarm Functions | Overload, phase fault, water shortage, over-temp | Overload, phase fault, oil shortage, over-temp, oil overflow |

| Safety | Safer at lower temps, risk of boiling | Safe for high temp, requires oil management |

| Application Fields | Injection molding, die casting, packaging | Rubber, chemical, high-temp plastic, pharmaceutical |

| Maintenance | Easier, less costly | Requires monitoring of oil quality and leaks |

| Cost | Lower initial & operating cost | Higher initial & maintenance cost |

Applications of Oil Temperature Control Unit

Oil Temperature Control Units (TCUs) are essential for processes requiring precise and high-temperature control. They are widely used in industries where thermal stability, consistent heating, and indirect cooling are critical. Here’s an expanded list of application scenarios:

Plastic and Rubber Industry

| Die Casting

| Chemical and Pharmaceutical Industry

|

Food and Beverage Processing

| Printing and Laminating

| Textile Industry

|

Battery and Electronics Manufacturing

| Laboratories and R&D Facilities

| Automotive and Aerospace

|

General Industrial Applications

|

|

|

Use Case Examples of Oil Temperature Control Unit by AODE

UNIT: Oil Temperature Control Unit

Model: AEOTX-75CL-36

Temperature Range: 45℃~260℃

Medium: Oil

Features: One unit integrates six independent temperature zones, enabling precise temperature control for six machines simultaneously.

AODE has been deeply focused on the field of industrial temperature control, backed by strong R&D resources and extensive practical experience. As both a professional oil temperature control unit manufacturer and a comprehensive temperature system solutions provider, AODE continues to lead the industry in innovation and reliability.

The AEOTX-75CL-36 oil temperature control unit is one of AODE’s flagship models, designed for high-performance and multi-point control, particularly suited for applications requiring efficient and stable oil heating. This model is ideal for the die casting temperature control of magnesium alloy, aluminum alloy, zinc alloy, and copper alloy.

AODE maintains long-term strategic partnerships with leading domestic and international equipment manufacturers as well as renowned research institutions. Our oil temperature control units are widely applied across various industries including automotive parts, communication components, electronics, home appliances, furniture parts, power tools, aerospace, high-speed rail, and defense industries, delivering precise and reliable thermal control in every application.

Specification Parameters of Oil Temperature Control Unit by AODE

High-Temperature Oil Temperature Control Unit(AEOT Series)

ITEM | UNIT | Model | |||||||

| AEOT-20 | AEOT-30 | AEOT-40 | AEOT-50 | AEOT-75 | AEOT-100 | AEOT-150 | AEOT-200 | ||

| Temp control range | ℃ | Inlet water temperature +45℃-300℃ | |||||||

| Temp control accuracy | ℃ | PID±1℃ | |||||||

| Power supply | 3N-380V-50Hz | ||||||||

| Heat transfer medium | Thermo conductive oil | ||||||||

| Cooling method | Indirect Cooling | ||||||||

| Expansion tank capacity | L | 24 | 67 | 67 | 67 | 100 | 150 | 200 | 300 |

| Heating capacity | KW | 12/24 | 30/36 | 60 | 60 | 60/90 | 90/120 | 120/180 | 180/240 |

| Pump power | KW | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Pump flow | m³/h | 6.5 | 10 | 12.5 | 16 | 12.5 | 25 | 45 | 50 |

| Pump pressure | m | 28 | 31 | 32 | 32 | 50 | 54 | 42 | 50 |

| Max. power consumption | KW | 25.5 | 38.2 | 63 | 64 | 95.5 | 127.5 | 191 | 255 |

| Alarm function | Inverse phase/Oil Shortage/Overheating/Overload/Oil Overflow/Abnormal Heating | ||||||||

| Cooling water pipe | inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | / | / | / |

| Circulating water pipe | inch | 1 | 1 | 1 | 1 | 1 | 1 | 1.5 | 2 |

| Size(L×W×H) | mm | 1200*440*1100 | 1470*500*1250 | 1720*550*1350 | 1720*550*1350 | 1690*600*1500 | 1690*600*1500 | 1780*650*1800 | 1750*800*1800 |

Standard Oil Temperature Control Unit(AOS Series)

ITEM | UNIT | Model | |||||

AOS-05(A) | AOS-10(A) | AOS-20 | AOS-30 | AOS-50 | AOSD-10 | ||

Temp control range | ℃ | Inlet water temperature +45℃-180℃ | |||||

Temp control accuracy | ℃ | PID±1℃ | |||||

Power supply | AC3∮380V 50Hz(3phase+Earth);AC3∮440V 60Hz;AC3∮460V 60Hz | ||||||

Heat transfer medium | Thermo conductive oil | ||||||

Cooling method | Indirect Cooling | ||||||

Heating capacity | KW | 6 | 9 | 9 | 18 | 24 | 9+9 |

Pump Horsepower | hp | 0.5 | 1 | 2 | 3 | 5 | 1+1 |

Pump flow | L/min | 30(22) | 85(30) | 120 | 150 | 240 | 85+85 |

Pump pressure | kg/cm² | 1.7(1.3) | 1.5(1.7) | 1.7 | 2 | 2.6 | 1.5 |

Max. power consumption | KW | 7 | 10 | 11 | 20.25 | 27.75 | 20 |

Alarm function | excess temperature/Open phase/oil starvation/ overloading/reverse turn | ||||||

Cooling water pipe | inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | - |

Circulating water pipe | inch | 3/8*2 | 3/8*4 | 3/8*4 | 1/2*4 | 3/4*4 | (3/8*4)*2 |

Size(L×W×H) | mm | 630*325*745 | 630*325*745 | 630*325*745 | 900*420*850 | 1400*500*1150 | 630*600*745 |

Weight | kg | 66 | 75 | 80 | 90 | 160 | 110 |

Remark: A. Volume of cooling water 20l/min(30℃.1kg/cm3), medium flow 50-100l/min B.Heating,cooling power or area ADDM-18/36 0.3㎡,ADDM-48/60 0.5㎡ C.About cold oil temperature is 200℃ D.The size of the equipment is only for reference,and the actual size of the equipment is accurate. | |||||||

Features of Oil Temperature Control unit by AODE

Features of High-Temperature Oil Temperature Control Unit by AODE

| Features of Standard Oil Temperature Control Unit by AODE◆ Explosion-proof equipment (optional) |

Video overview of oil temperature control unit by AODE

Troubled by your oil temperature machine's slow heating process? Follow our recommendations for a fast and effective solution. Watch the video below to learn how an oil temperature control unit works.