9KW Portable Air Chiller Unit with 15℃-120℃ PID±1℃ Temp Control for Industrial Use

Product Details:

| Place of Origin: | Air Chiler Factory |

| Brand Name: | AODE |

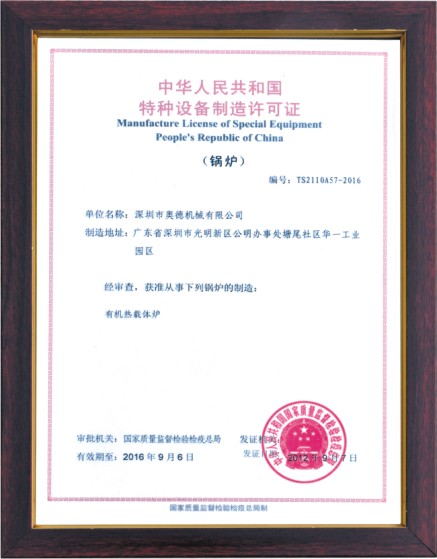

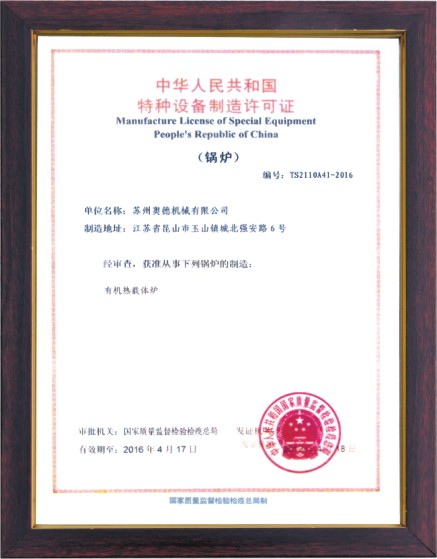

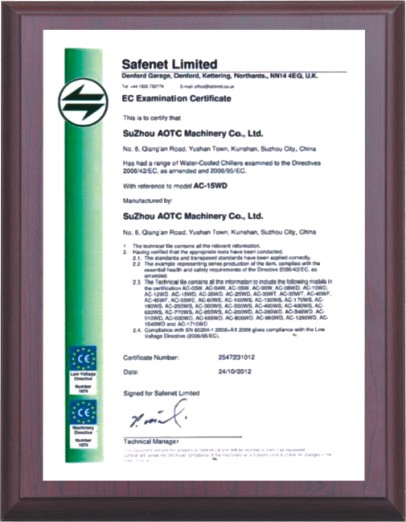

| Certification: | ISO, CE, ROHS |

| Model Number: | AWM-20 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | $ |

| Packaging Details: | Protective/air bubble film, Wooden case. As client’s require |

| Delivery Time: | Within 20days after receiving |

| Payment Terms: | 30% T/T in advance, 70% balanc |

| Supply Ability: | 500pcs/month |

Descriptions of this Portable Air Chiller Unit

This 9KW Portable Air Chiller Unit is an advanced industrial cooling solution designed for die casting, plastic injection molding, printing, rubber presses, and chemical processing. It features a temperature control range of 15℃-120℃ with PID±1℃ accuracy, ensuring precise thermal regulation. The direct cooling system with water as the heat transfer medium provides efficient and stable performance. With a maximum power consumption of 11KW, a high-efficiency 2HP water pump delivering 150L/min flow at 1.8Kg/cm² pressure, and RS485 communication for automated management, this unit offers reliable operation, energy efficiency, and advanced safety protections, making it ideal for demanding industrial applications.

Detailed Informations of 9KW Portable Air Chiller Unit with 15℃-120℃ PID±1℃

| Brand Name: | AODE | Application: | Die Casting, Plastic Injection Molding, Pringting, Rubber Presses, Chemical |

|---|---|---|---|

| Certification: | CE | Cooling Method: | Direct Cooling |

| Heat Transfer Medium: | Water | Heating Energy: | 9KW |

| Maximum Power Consumption: | 11KW | Power Supply: | AC3∮380V 50HZ 3P+E(5M) |

| Temp Control Accuracy: | PID±1℃ | Temperature Range: | 15℃-120℃ |

| High Light: | Portable Air Chiller Unit, 9KW Portable Air Chiller Unit, Portable Air Chiller Unit with 15℃-120℃ PID±1℃ Temp Control | ||

Specifications of 9KW Portable Air Chiller Unit with 15℃-120℃ PID±1℃ Temp Control

ITEM | UNIT | AWM-20 |

Temp control range | ℃ | Inlet water temperature +15℃-120℃ |

Temp control accuracy | ℃ | PID±1℃ |

Power supply | AC3∮380V 50HZ 3P+E(5M) | |

Heat transfer medium | Water | |

Cooling method | direct Cooling | |

Heating capacity | KW | 9 |

Horsepower of pump | hp | 2 |

Working flow of pump | L/min | 150 |

Working pressure of pump | Kg/cm2 | 1.8 |

Max. power consumption | KW | 11 |

Alarm function | Open phase/water depletion/excess temperature/overloading/reverse turn | |

Cooling water pipe | inch | 1/2 |

Circulating water pipe | inch | 3/8×4 |

Size(L×W×H) | mm | 620×325×645 |

Weight | kg | 75 |

Key Features & Functions of 9KW Portable Air Chiller Unit

Precise Temperature Control: Supports 15℃-120℃ temperature range with PID±1℃ accuracy for stable performance.

Efficient Cooling Method: Direct cooling system using water as the heat transfer medium, ensuring rapid heat dissipation.

High Heating Capacity: 9KW heating power with an advanced switchover heating power function for flexible operation.

Reliable Water Pump Performance: 2HP water pump with 150L/min flow rate and 1.8Kg/cm² pressure for continuous and stable circulation.

Advanced Safety System: Multi-layer protection with alarms for excess temperature, open phase, oil starvation, overloading, and reverse turn.

Smart Automation: Optional RS485 communication for seamless integration into automated production systems.

Compact & Portable Design: Lightweight (75kg) and 620×325×645 mm dimensions for easy installation and mobility.

Popular Selling Points

✅ Wide Industrial Application – Ideal for die casting, plastic injection molding, rubber presses, printing, and chemical processing.

✅ Energy-Efficient – Maximum power consumption of only 11KW, optimizing energy use while maintaining high performance.

✅ Durable & Corrosion-Resistant – Stainless steel integrated pipelines minimize pipe resistance and prevent rusting.

✅ High-Quality Components – Equipped with OMRON, FUJI, TE, LG, MOELLER, ABB, and WEST branded electrical parts for reliable operation.

✅ Flexible Customization – Offers multi-point temperature control unit and customizable horsepower & heating power of the water pump.

✅ Enhanced User Safety – Includes automatic air-exhausting function, BY-PASS pressure release loop, and explosion-proof equipment (optional).

Best-Suited Manufacturing Environments

| Business Scale | Application Scenarios |

|---|---|

| Small & Medium Enterprises (SMEs) | Ideal for compact workshops and precision manufacturing where space and energy efficiency matter. |

| Large-Scale Factories | Suitable for mass production lines that require consistent temperature regulation to ensure quality control. |

| Industries with Strict Temperature Control Needs | Ideal for chemical engineering, rubber processing, and precision molding industries requiring precise heating and cooling cycles. |

Installation & Usage Guide

Placement: Position on a flat, stable surface to prevent vibrations and ensure optimal performance.

Power Connection: Ensure AC3∮380V 50HZ 3P+E (5M) power supply is properly connected before operation.

Water Inlet/Outlet Setup: Connect to the appropriate cooling water pipe (1/2 inch) and circulating water pipe (3/8×4 inch) for seamless operation.

Initial System Check: Inspect piping connections, pressure settings, and safety alarms before turning on the unit.

Operational Settings: Adjust temperature range (15℃-120℃) via the PID controller based on process requirements.

Monitoring & Maintenance: Periodically check water levels, pressure, and alarms to ensure long-term reliability.

Customization Options

| Customizable Features | Description |

|---|---|

| Multi-Point Temperature Control | Allows precise management of multiple cooling zones. |

| Heating & Water Pump Horsepower | Can be tailored to different industrial needs. |

| Explosion-Proof Equipment | Optional feature for high-risk environments. |

| RS485 Communication | Enables remote monitoring and automation. |

| Automatic Air-Exhausting Function | Ensures smooth startup and prevents airlocks. |

Key Purchasing Considerations

| Factor | Details |

|---|---|

| Cooling & Heating Capacity | Ensure 9KW heating and 15℃-120℃ control range suits your process needs. |

| Power Supply Compatibility | Check if your facility supports AC3∮380V 50HZ 3P+E (5M). |

| Water Flow & Pressure | Verify if the 2HP pump with 150L/min flow & 1.8Kg/cm² pressure matches your system. |

| Safety Features | Consider alarms for overheating, oil starvation, and phase loss. |

| Integration Needs | If automation is required, opt for RS485 communication support. |

| Customization Options | Determine if multi-point temperature control or explosion-proof features are necessary. |

FAQs for Portable Air Chiller Unit

1. What is the temperature control range of the Portable Air Chiller Unit?

Answer: The Portable Air Chiller Unit offers a temperature control range of 15°C to 120°C, providing precise PID±1°C accuracy to maintain consistent performance in industrial applications, ensuring that your processes are always at optimal temperatures.

2. What is the heating capacity of this Portable Air Chiller Unit?

Answer: This unit comes with a 9KW heating capacity that can quickly and efficiently manage heating needs in various industries such as die casting, plastic injection molding, and chemical processing. The switchover heating power function offers flexibility in different operational conditions.

3. What makes the Portable Air Chiller Unit energy-efficient?

Answer: The Portable Air Chiller Unit is designed for energy efficiency, with a maximum power consumption of just 11KW. This makes it an ideal choice for small to medium enterprises (SMEs), where reducing energy costs is a priority while still maintaining high-performance standards.

4. Can the Portable Air Chiller Unit be used for automated systems?

Answer: Yes, the Portable Air Chiller Unit comes with an optional RS485 communication function that enables seamless integration into automated systems. This feature allows for remote monitoring and control, enhancing your operational efficiency and reducing manual intervention.

5. What safety features does the Portable Air Chiller Unit have?

Answer: The unit includes multiple safety features, such as alarms for excess temperature, open phase, oil starvation, overloading, and reverse turn. These ensure the unit operates within safe parameters, preventing damage and enhancing longevity. Additionally, the BY-PASS pressure release loop further enhances safety during operation.

6. What industries are best suited for the Portable Air Chiller Unit?

Answer: The Portable Air Chiller Unit is versatile and suitable for industries such as die casting, plastic injection molding, rubber presses, chemical processing, and printing. It is perfect for environments where precise temperature control and energy efficiency are critical for production quality and system performance.

Address: No.37,Dayang Industrial Area, Xingang East Road, Lougang Boulevard, Songgang Town, Bao'an District, Shenzhen

- Tel:0086 13682516936

- Email: tina.shi0721@foxmail.com

- Worktime:8:00-02:00

- Contact Person:Miss. Tina Shi

- Mobile Site